Introduction to Barrier Materials

When it comes to construction and renovation, choosing the right barrier material can make all the difference. Whether you’re dealing with moisture control, vapor barriers, or ground protection, selecting a reliable product is crucial for long-lasting results. Among various options available on the market today, Visqueen stands out as a popular choice. But what makes this material so special? And how does it compare to others in its category? Let’s dive into the world of barrier materials and explore everything you need to know about Visqueen versus its competitors.

What is Visqueen?

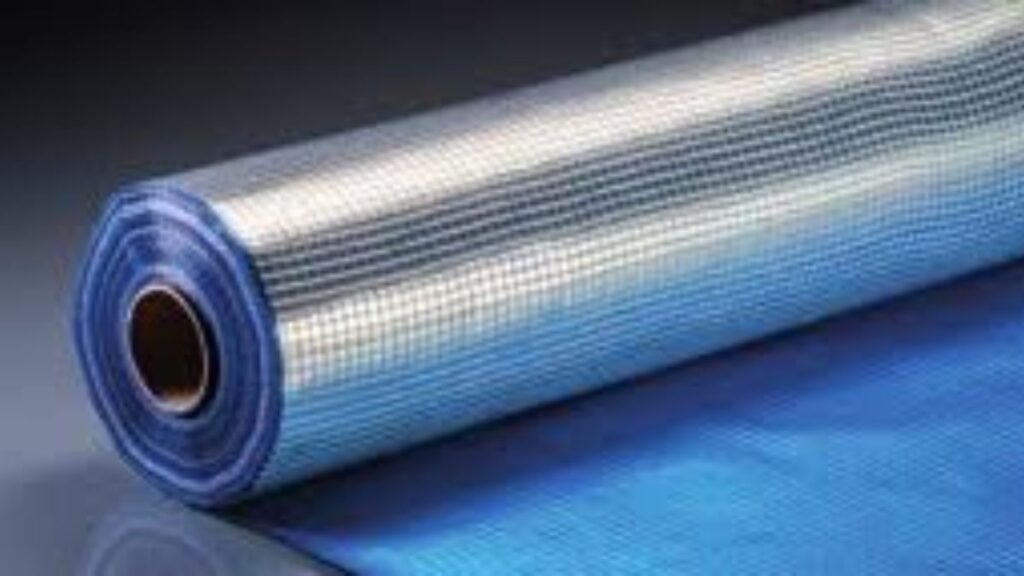

Visqueen is a brand name synonymous with high-quality polyethylene sheeting. This versatile material is often used in construction, landscaping, and various industrial applications.

Known for its durability and flexibility, Visqueen provides an effective barrier against moisture and contaminants. It’s available in different thicknesses to suit specific project needs, making it adaptable for multiple uses.

The material’s lightweight nature makes it easy to handle while still being robust enough to withstand tough conditions. Whether you need protection from water damage or require a vapor barrier for your foundation work, Visqueen stands out as a reliable choice.

It’s also UV resistant when treated properly, which extends its life when exposed to sunlight. Its broad range of applications has made it a favorite among builders and contractors alike.

Benefits of using Visqueen

Visqueen offers a range of benefits that make it a top choice for various applications. Its durability stands out, providing long-lasting protection against moisture and environmental conditions. This resilience ensures projects remain intact over time.

Another advantage is its versatility. Visqueen can be used in construction, landscaping, and even packaging. Whether you need to protect surfaces or create barriers, it adapts easily to your needs.

Additionally, the material is lightweight yet strong. This combination simplifies installation without compromising effectiveness. Workers appreciate how manageable it is on-site.

Moreover, Visqueen’s resistance to chemicals makes it ideal for industrial use. It safeguards sensitive areas from harmful substances effectively.

The cost-effectiveness of Visqueen makes it an appealing option for budget-conscious projects. You get reliable performance without breaking the bank.

Comparison of Visqueen with other barrier materials

Visqueen stands out among barrier materials due to its flexibility and durability. Unlike traditional polyethylene sheets, it offers superior puncture resistance, making it ideal for various applications.

Other materials like Tyvek provide breathability but may not offer the same moisture protection as Visqueen. This makes Visqueen a better choice for projects where water infiltration is a concern.

When comparing with concrete curing blankets, Visqueen’s lightweight nature allows for easier installation and handling. However, those blankets excel in insulating properties during colder months.

In contrast to thicker barriers like EPDM rubber membranes, Visqueen is often more cost-effective while still providing reliable performance in damp environments. Each material has strengths that cater to specific needs; understanding these differences can guide you toward the right choice for your project.

When to use Visqueen and when to use other barrier materials

Visqueen is ideal for moisture control in construction and renovation projects. Its durability makes it perfect for foundations, crawl spaces, and under concrete slabs. When you need a reliable barrier against water intrusion, Visqueen shines.

On the other hand, consider alternatives like Tyvek or polyethylene sheeting when air infiltration is a concern. These materials provide excellent protection against drafts while allowing moisture vapor to escape.

For environments with extreme temperatures or chemical exposure, specialized membranes might be more effective than Visqueen. Choose options designed specifically for those conditions to ensure long-lasting performance.

When dealing with landscaping and gardening projects, lightweight plastic sheets can serve as temporary barriers. They are easy to handle but may not offer the same level of durability as Visqueen.

Evaluate your specific needs carefully before making a choice between Visqueen and other barrier materials. Each has its strengths depending on the application at hand.

Tips for using Visqueen effectively

To use Visqueen effectively, start by selecting the right thickness for your project. Thicker sheets provide better durability and protection but may be more challenging to handle.

Ensure a clean surface before application. Dirt or debris can compromise adhesion and performance.

When laying down Visqueen, overlap seams by at least 12 inches. This extra coverage helps prevent moisture penetration, which is crucial in damp environments.

Using tape designed for plastic sheeting can enhance seal integrity. Make sure to apply it firmly along all edges and seams.

Consider using weights or stakes to secure the material against wind during installation, especially outdoors.

Always check local regulations regarding barrier materials in construction projects to ensure compliance with building codes.

Conclusion

Barrier materials play a crucial role in construction and various applications, providing protection against moisture, air, and other environmental factors. Choosing the right material can significantly affect the durability and performance of your project.

Visqueen is a well-known brand that offers high-quality polyethylene sheeting. Its versatility makes it suitable for many industries, including construction, agriculture, and packaging.

Using Visqueen comes with numerous advantages. It boasts excellent resistance to moisture and chemicals while being lightweight yet durable. This combination helps ensure that projects remain protected from unwanted elements over time.

When comparing Visqueen with other barrier materials like Tyvek or EPDM rubber sheets, each has its strengths. While Tyvek excels at breathability for house wraps, Visqueen shines in waterproofing applications due to its impermeable nature. EPDM rubber may offer superior longevity but tends to be more expensive than Visqueen.

The choice between using Visqueen or another barrier material largely depends on specific needs. For instance, if you require an effective vapor barrier for a basement project or crawl space encapsulation, then opting for Visqueen might be ideal. However, when working on residential exteriors where breathability is essential for moisture management within walls, alternatives like Tyvek could serve better.

To maximize the effectiveness of your chosen product—especially if it’s Visqueen—consider these tips: Ensure proper installation by overlapping seams appropriately; secure edges firmly using tape designed for polyethylene; store away from direct sunlight before use to prevent degradation; monitor conditions during application to maintain optimal adhesion.

Choosing between different barrier materials doesn’t have to be overwhelming when armed with the right knowledge about their properties and applications! Whether you lean towards selecting durable poly sheeting like Visqueen or exploring alternatives suited specifically for unique tasks ahead will define not just results but overall satisfaction too.