In the arena of present-day production, coordination is the whole lot. Mechanical, electrical, and plumbing (MEP) structures are the lifeblood of any building; however, they also represent some of the most complex, interdependent components. One out-of-place duct or misaligned conduit can put off setup, inflate charges, or even require full redesigns. That’s where CAD Drafters and Construction Estimating Services come together as the silent problem-solvers at the back of every green MEP undertaking.

The Role of Precision in MEP Planning

Every MEP challenge starts long before materials arrive on the page. It starts off with precision drawings and fact-based estimates.

A CAD Drafter transforms engineering concepts into technical blueprints—plans that guide contractors, fabricators, and installers. When those drawings are built accurately, the rest of the task follows a clean route.

Yet drafting on my own isn’t enough. Parallel to design, MEP Estimating Services analyzes portions, labor, and materials to forecast the monetary side of the build. Together, they create a synchronized machine: one crew defines what is going to be constructed, while the other defines how many tons it’s going to cost and how long it’ll take.

Why Accuracy Defines Success

An out-of-place pipe or the wrong size can ripple through an entire venture.

When a CAD Drafter works hand-in-hand with an estimator, capability mistakes are caught early—before they reach the sphere.

Accurate drafting ensures that quantities in the estimates healthy the realities of the construct.

This coordination results in fewer change orders and fewer financial overruns.

In an enterprise where margins are tight, small errors may have large economic consequences. That’s why many firms now pair Construction Estimating Services at once with CAD drafting departments throughout the pre-creation phase.

Practical outcomes of this partnership encompass:

- Early detection of layout conflicts between HVAC, plumbing, and electrical runs.

- Fewer delays resulting from missing or miscalculated substances.

- Cost savings via optimized layouts and decreased waste.

- Smoother coordination among the workplace and discipline teams.

The Power of Integrated Digital Models

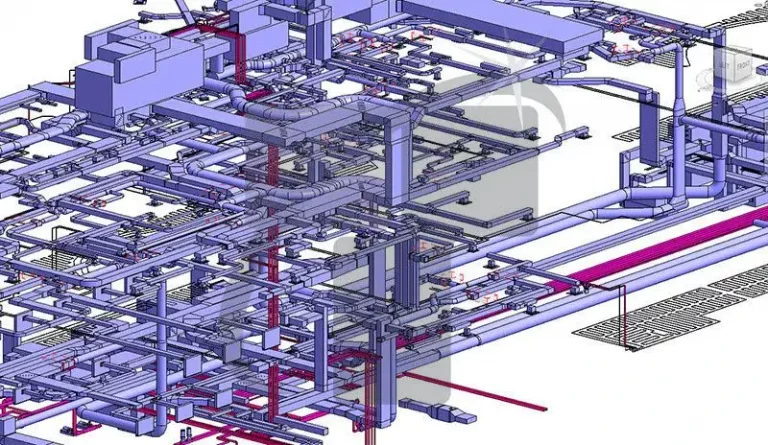

Traditional 2D plans used to dominate MEP coordination; however, that technique left plenty of room for human mistakes. Today, most CAD Drafters use superior modeling software to create 3D environments where every pipe, duct, and cable may be visualized in context.

This virtual basis makes it possible for estimators to pull records without delay from the model. Instead of manually counting furniture or fittings, they can link takeoff tools to the version itself. That way, the estimate updates automatically because the layout evolves.

The connection between CAD drafting and MEP Estimating Services guarantees that nobody is operating from old information. When a designer adjusts a pipe run or modifications a duct size, the estimator right away sees the impact on the fee and materials. This dynamic feedback loop shortens decision time and makes each section of production greater predictable.

Streamlining Complex Coordination

MEP estimating services hardly ever exist in isolation. They share space with structural beams, ceilings, fireplace structures, and architectural finishes. That’s why coordination between disciplines is certainly one of the most important challenges in production.

A CAD Drafter brings precision to version each system layer appropriately. But without accurate price forecasting, even the excellent layout can falter beneath price range strain.

Construction Estimating Services stability this via aligning the design with economic feasibility.

Together, they help undertake groups:

- Identify spatial conflicts early with coordinated three-D fashions.

- Allocate budgets based on real global quantities.

- Adjust layouts earlier than procurement to prevent area problems.

- Ensure that subcontractors have clean, battle-unfastened drawings.

When handled well, this collaboration eliminates the “reactive” approach that regularly plagues MEP tasks. Instead of solving problems on site, groups remedy them on display—long before production begins.

Reducing Rework and Field Delays

Rework is one of the most high-priced and time-consuming issues in MEP construction.

Poor documentation, unclear drawings, or erroneous estimates regularly cause miscommunication between layout and setup groups.

When CAD Drafters and MEP Estimating Services work in tandem, rework drops dramatically. Clear, dimensionally precise drawings make certain that trades understand precisely where additives move. Meanwhile, estimators provide a verified list of substances, removing guesswork.

Common time-saving practices include:

- Layered CAD drawings for each field with coloration coding.

- Clash detection to save you from overlaps among systems.

- Centralized document management to ensure certain groups use the modern version.

- Coordinated schedules that link drawing updates to estimate revisions.

This approach improves not only efficiency but also morale. Field people consider the drawings they’re constructing from, and assignment managers benefit self self-belief in budgets that maintain regular thru crowning glory.

Enhancing Communication Across Teams

A nicely-skilled CAD Drafter acts as a bridge between design rationale and area execution. Their drawings use a frequent technical language.

When mixed with facts from Construction Estimating Services, those drawings rework right into a roadmap that everyone—from undertaking proprietors to electricians—can rely on.

Communication turns into visible, measurable, and immediate. Estimators interpret linework into quantities and expenses, at the same time as drafters translate comments from website teams into clearer documentation. That loop strengthens every level of the undertaking lifecycle.

The Long-Term Benefits of Collaboration

The proper fee for integrating CAD drafting and estimating isn’t confined to a single venture. Over time, teams broaden libraries of correct components, pricing histories, and standardized workflows.

Future tasks start quickly because the basis is already constructed.

Long-term profits include:

- Consistent drawing requirements that simplify training and reviews.

- Historical price records tied at once to real design additives.

- Faster turnaround for bids and recommendations.

- Enhanced patron accept as true with thru predictable performance.

With MEP Estimating Services feeding actual records into layout tools, destiny estimates come to be even sharper and more aggressive.

Conclusion: A Smarter, Faster Way to Build

The fulfillment of an MEP challenge depends on clarity, coordination, and foresight.

By combining Construction Estimating Services with the technical know-how of a CAD Drafter, contractors and engineers do away with the guesswork that frequently slows development.

These partnerships turn complicated, demanding situations into viable workflows—drawing via drawing, estimate with the aid of estimate.

In the quit, streamlined collaboration doesn’t just save money and time; it builds confidence across the whole production chain.

Accurate drawings. Realistic estimates. Fewer surprises.

That’s the destiny of MEP production—where technology and teamwork meet precision and cause.