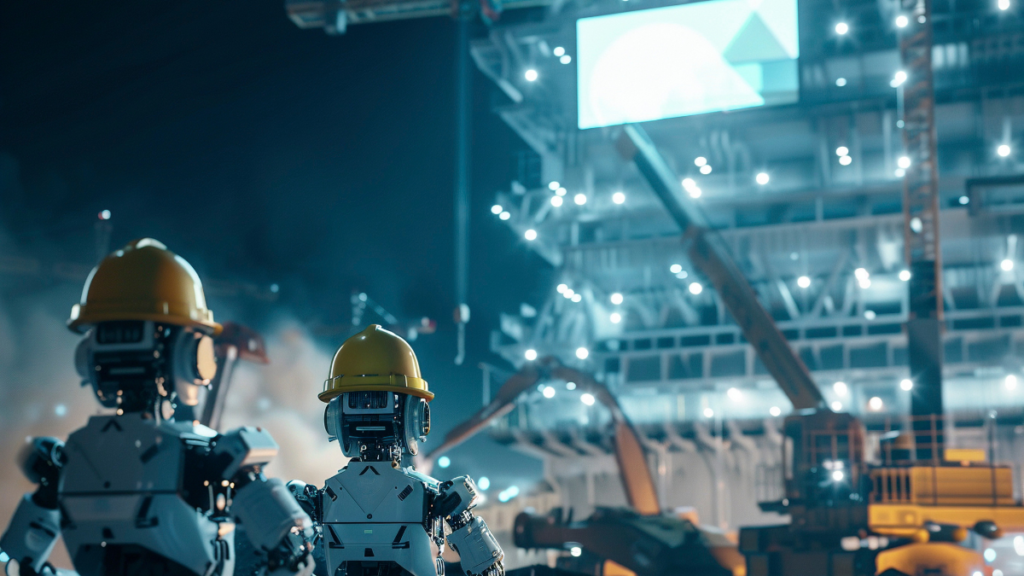

The mining industry is experiencing a significant transformation due to the adoption of new technologies. One of the leading advancements in this field is the implementation of mining automation solutions. These solutions not only augment operational efficiency but also considerably improve safety across mining sites.

The Rise of Automation in Mining

As industries strive for higher productivity and cost-effectiveness, mining companies are increasingly turning to automation. Automated machinery can operate continuously without fatigue, leading to longer operational hours and stable productivity rates. The deployment of automated devices helps in reducing human intervention in hazardous areas, thereby enhancing safety.

Enhancing Efficiency with Automation

Mining automation solutions enable precise control over mining equipment, reducing waste and optimising resource use. Automated systems can monitor and adjust operations in real-time, leading to more efficient resource extraction. This technological advancement allows mines to operate at peak efficiency, making better use of available resources and reducing operational costs.

Operational Flexibility

One of the major benefits of automation is the flexibility it provides. Automated equipment can quickly adapt to different mining conditions, which is crucial in the ever-changing environments of mining sites. This adaptability not only boosts productivity but also allows companies to respond swiftly to market demands.

Safety Improvements Through Automation

Safety is a primary concern in the mining industry, known for its hazardous working environments. Automation significantly mitigates these risks by reducing the need for human presence in dangerous areas. Remote-controlled machinery and automated safety systems minimise the exposure of workers to potential hazards, leading to a safer working environment.

Real-time Monitoring and Data Analytics

With mining automation solutions, operators can leverage real-time data analytics to make informed decisions that enhance safety and operational efficiency. Real-time sensors and monitoring equipment track equipment performance, geological conditions, and worker safety metrics, ensuring better oversight and rapid response to potential safety issues.

The Economic Impact of Automation

Implementing automation not only boosts efficiency and safety but also has significant economic advantages. By reducing the reliance on manual labour, companies can allocate resources more effectively, lowering operational costs. Automated operations often require fewer human resources, which can translate into reduced labour costs and subsequently higher profit margins.

Reducing Environmental Impact

Automation also plays a role in minimising the environmental footprint of mining operations. Precision and efficiency in resource extraction mean less waste, and advanced systems are often more energy-efficient. These factors contribute to a reduced environmental impact, aligning with global sustainability goals.

Challenges and Considerations

Despite the many advantages of mining automation solutions, there are challenges to consider. The initial investment in automated equipment can be substantial, and there is a learning curve associated with new technology implementation. Companies must also address potential job displacement issues and ensure that workers are provided with reskilling opportunities.

The Future of Mining Automation

Looking forward, the role of automation in mining is expected to grow. Continued advancements in technology promise even greater improvements in efficiency, safety, and sustainability. As more companies adopt these technologies, it will likely lead to industry-wide changes, setting new standards for mining operations worldwide.

Conclusion

Mining automation solutions represent a transformative approach to enhancing both efficiency and safety within the industry. By leveraging these technologies, mining companies can not only achieve higher productivity and cost savings but also create safer working conditions and reduce environmental impacts. Embracing automation is key to the sector’s future competitiveness and sustainability.