Do you need plain yet secure packaging for your products? Get your hands on custom tuck boxes. These are simple-looking packaging boxes with the main purpose of packing your items. Thanks to their versatility, you can use them for the packaging of multiple items, regardless of their nature. But this packaging is not only limited to just the housekeeping of the goods; it also offers plenty of other benefits, including branding and marketing. To learn about these humble yet useful boxes, let’s have a look at this guide.

What are Custom Tuck Boxes?

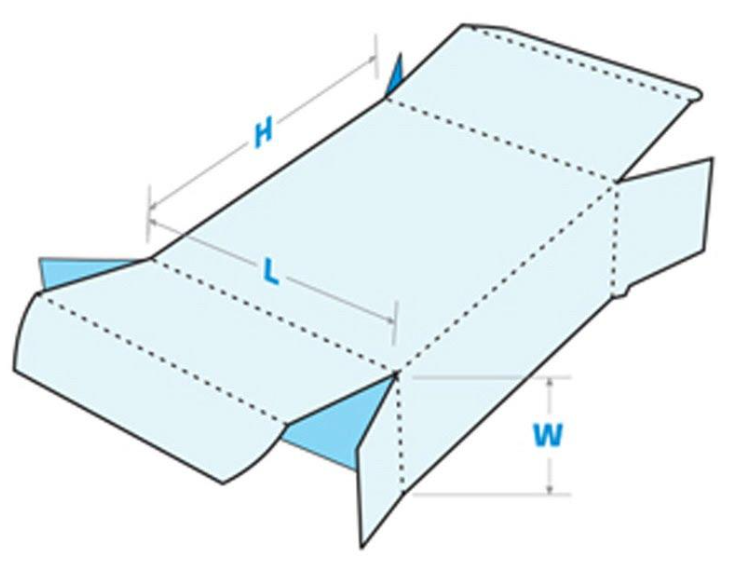

Looking at their physical outlook, custom tuck end boxes present a straightforward look. They have a anybody design, which means they are made of one single continuous design, where both ends are joined with glue during the assembly process. The sides of the packaging protrude outwards to create a flap-like structure. These kids are designed in such a way that they can easily be fixed in the receiving ends of the build for the creation of a strong closure.

The beauty of this packaging is that it can be crafted with any typical available material. For example, you can use cardboard if durability is your purpose. You can go with a paperboard if you are looking for a lightweight aspect. Further, choose Kraft for a strong yet green stock for your products. On top of that, you can make them highly attractive by opting for various alluring customizations, such as coiling or foiling.

Types of Tuck End Boxes

As explained earlier, one of the major reasons that the brands opt for tuck-end boxes is their flexibility. Owing to their simple style, they are quite adaptable, allowing brands to use the same box for different purposes. For example, one of their most common uses is playing card tuck boxes, where they act as abodes for the deck of cards. Let’s explore some more applications of these boxes below:

1. Straight Tuck End Boxes (STE): This type has both tucks on the same side. These boxes are designed where a speedy assembly process is required or when you are looking to pack lightweight items in the packaging. They are also ideal for scenarios where a clean look is required.

2. Reverse Tuck End Boxes (RTE): The RTE type is preferred when you need secure packaging. Reverse tuck end boxes have flips on the opposite sides, letting them protect the items while maintaining the look.

3. Snap Lock Tuck End: Known as custom 123 boxes or Houghland packaging, snap lock tuck end boxes are designed for ultimate protection. Their base has a system that automatically locks in place during the assembly process. You can choose this packaging if top-notch protection is in your view.

4. Seal Tuck End Boxes: This type is pretty similar to the Snap Lock one; the only difference is that its base is sealed with glue. In fact, they are pre-glued from the factory, allowing you to only close the other end during the packaging process. In this way, you can optimize the laborer’s work process.

5. Die Cut Tuck Boxes: This packaging type has a window cut that is used to give a sneak peek of your items to the buyers. The goal of such boxes is to enhance the visual appearance and make them more appealing to the users.

Why are Tuck Boxes so Important?

Personalized tuck boxes are one of the most preferred boxes by style. There are a number of reasons that they have become the public darlings of the brands. For example, they offer bespoke brand recognition. You can customize your packaging in whatever way you want to make yourself distinctive from others. This will create a market differentiation for you, letting you have a high place among your rivals.

As mentioned above, protection is the key role of this packaging. With their strong build and sturdy flaps, they add a superb security aspect to your lineup. On top of that, you can also leverage things like coating or lamination to take this security aspect to the next level.

Another nuanced yet crucial aspect of this packaging is the ease of use. They are designed in a way that the buyers can easily open the boxes while accessing the inside contents. This also saves the labor time and reduces the operation costs. Some other gains of adding tuck-end packaging are their affordability as well as sustainability.

Custom Printing for Your Boxes

There are 2 phases of designing a box; one is the template preparation, and the other is the designing. Once you have ready your base design, the next process is to shift on your boxes. For this, you can get help from custom printing. There is a wide range of printing exists in the market; the most typical ones are given below:

- Digital printing: This is the most usual type of printing and is preferred by brands due to its affordability. Digital printing is also utilized when you have a small batch of fewer than 500 boxes and need quick output. The results produced by digital printings are not very durable and are prone to quick changes.

- Offset printing: A premium type of printing, the offset is utilized when you want long-lasting and strong results. This type yields outputs in the form of both CMYK and RGB, ensuring the durability of the prints. Due to its high cost per unit, it is only used when you want to print custom tuck boxes at a wholesale rate.

- Screen printing: This type also gives bold and punchy colors and can be used for even small batches. However, the process of screen printing is quite slow as it employs manual work and can be costly for large batches.

- 3D Printing: This is the latest type of printing and produces results in 3D format. Although not practical, brands can utilize this type to order a template before the final production begins. This type lets you get a hands-on experience of the box types.

Grab Market with Different Customizations

When it comes to grabbing the buying power of the market, custom tuck boxes with logos can offer a lot of help. They come with various finishes that render your boxes engaging, making them appealing to the shoppers. Some of these finishes are mentioned below:

Lamination: It is the process that involves the wrapping of one single yet transparent sheet of plastic around the boxes. This gives them a shiny appearance as well as protection from smudges and scratches.

Coating: If you need to double the protection as well as make the boxes engaging, use a coating. In this process, you spray a liquid over the boxes that dry under natural or UV light, making your design highlighted.

Foiling: Foil stamping in packaging refers to a process that uses a metallic or pigmented foil on the surface of the boxes. This gives them a shiny and eye-catching appearance, which can be leveraged to grab the market audience. There are two types of foiling: hot and cold. The former uses heat, while the latter works without any heat.

Specialty touches: If you need to engage your buyers tactically, specialty touches can be employed. They have 2 types; embossing and debossing. Embossing is used to give a raised effect on your packaging, while debossing produces a regressed effect.

If you are planning to add custom tuck boxes to your product packaging lineup, the best place to order is Packaging Mania. We have a team of experts that can guide you on how to make your boxes more alluring. On top of that, we offer free design support to ensure that you get the custom-made design as per your needs. Order now to avail up to 30% discounts.